LEWA Smart Monitoring

Con bombas digitales que permiten aumentar la eficacia, la disponibilidad del sistema y la rentabilidad del conjunto de la producción.

LEWA Smart Monitoring es un sistema de monitorización compuesto por sensores, un controlador lógico programable (PLC) y un PC industrial (IPC) para el análisis de datos para bombas tanto nuevas como en funcionamiento. El sistema determina los valores característicos y los indicadores clave de rendimiento. No hay intervención en el control del proceso ni contacto directo entre el sistema de sensores y el fluido transportado.

Con la monitorización del estado basada en indicadores clave de rendimiento, detectará y controlará los estados de funcionamiento de manera proactiva. También puede optimizar el rendimiento general y la solidez de sus sistemas de bombas y tuberías. Esto aumentará la eficiencia de toda su planta de producción. Puede acceder a los datos cómodamente a través de su red corporativa. O puede utilizar la cloud de LEWA con amplias posibilidades de análisis y servicio.

Ventajas

Ventajas de LEWA Smart Monitoring:

- Seguimiento permanente de los principales indicadores de rendimiento

- Entrega de estados de error en texto plano con la localización exacta del error

- Los valores estadísticos necesarios para evaluar el sistema de tuberías y el estado del fluido transportado

- Datos históricos para el análisis del funcionamiento y el cálculo de la rentabilidad en función del rendimiento de las bombas

- Conexión de datos al centro de control local a través de la interfaz estándar OPC UA

- Conexión al portal de clientes de la LEWA para servicios adicionales

- Ofertas de servicio exclusivas para nuestros clientes de Smart Monitoring

Diagnóstico y métricas de rendimiento

El tablero de diagnóstico.

Con LEWA Smart Monitoring tendrá acceso a varios parámetros de diagnóstico y rendimiento de su bomba y del sistema de tuberías conectado. Esto le permite detectar condiciones irregulares en el proceso y el estado de las piezas de desgaste en una fase temprana mediante un sencillo sistema de semáforo.

Tecnología y principio de funcionamiento

Cómo los datos sin procesar se convierten en valores representativos:

La determinación de valores representativos se basa en el registro de las variables medidas, como la vibración, la presión hidráulica y el ángulo de giro. Para obtener resultados, se procesan 2000 señales por cabeza de bomba cada segundo. Estas señales son medidas por el PLC conectado.

Vídeo

La salida y transmisión de los valores y diagnósticos se realiza a través de varias interfaces:

LEWA Smart Monitoring

LEWA Smart Monitoring es un sistema de monitorización de estado para su bomba LEWA. Con el sistema siempre tendrá a la vista el estado actual de sus bombas en funcionamiento. El mantenimiento puede llevarse a cabo de forma selectiva. Con la predicción del desgaste se pueden evitar paradas no planificadas.

Datos técnicos

La salida y transmisión de los valores y diagnósticos se realiza a través de varias interfaces:

El IPC dispone de una interfaz basada en web en la que se pueden realizar ajustes y se visualizan los valores y diagnósticos. Se proporciona un servidor OPC UA para la transmisión a un centro de control. Además, los valores estadísticos y los diagnósticos pueden enviarse a la cloud de LEWA y al portal de clientes de LEWA a través de una conexión a Internet.

| Properties | Expression |

|---|---|

| Supported pump types | LEWA ecoflow LEWA triplex |

Sensor technology (for applications up to 150 °C operating temperature) | Vibration Hydraulic pressure Trigger Optional: temperature, diaphragm rupture and motor power |

| Hardware | 16 bit A/D converter with 1 kHz sampling rate |

| Cloud | Cloud connectivity via Microsoft Azure cloud for value-added services |

| Security | Encrypted communication |

| Operating zones | Sensors certified up to zone 1 |

| Interfaces | Direct data access via OPC UA interface and TCP/IP protocol |

Productos

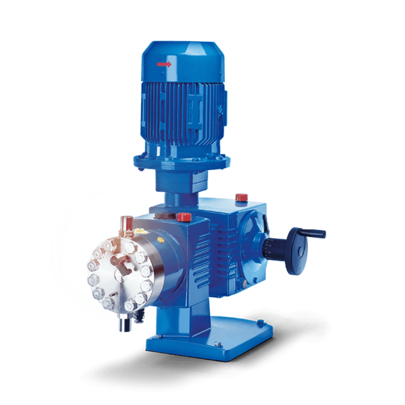

Bomba dosificadora de membrana LEWA ecoflow®

LEWA ecoflow es una innovadora bomba dosificadora universal con sistema de protección de membrana DPS en un sistema modular de eficacia probada. Adecuada para múltiples aplicaciones, la ecoflow es nuestro verdadero talento todoterreno en la que confían clientes de todos los sectores.

More DetailsBomba dosificadora de membrana LEWA ecoflow® sanitaria/higiénica

LEWA ecoflow también está disponible en el modelo sanitario/higiénico. La bomba dosificadora para aplicaciones higiénicas posee las mismas propiedades generales y cumple todas las especificaciones para la producción farmacéutica y de alimentos.

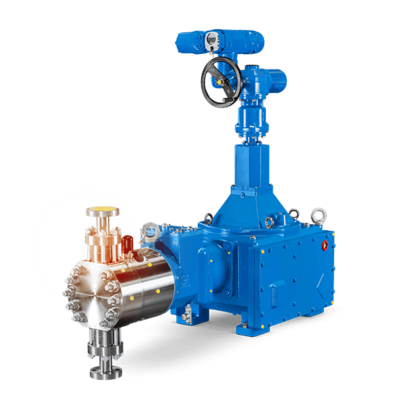

More DetailsBombas de ecoflow® proceso LEWA para aplicaciones de alta presión

La innovadora bomba de membrana de proceso ecoflow demuestra sus cualidades en aplicaciones de alta presión en el sector del petróleo y el gas, refinerías e industrias petroquímicas, así como en el delicado sector farmacéutico, biotecnológico y de producción de alimentos y bebidas.

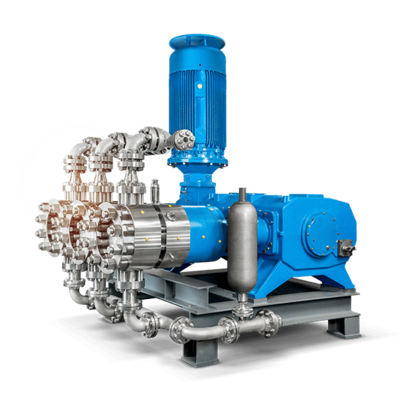

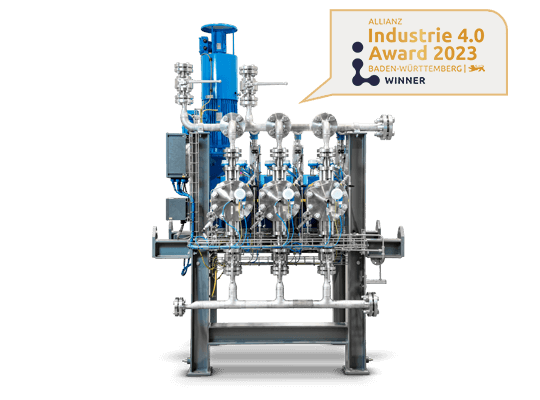

More DetailsBombas de proceso LEWA triplex® para proceso de alta presión

La bomba de membrana de proceso LEWA triplex® cuenta entre las bombas de alta presión más compactas del mundo y puede incluso montarse en los lugares más angostos, cuando el ahorro de espacio es vital. Este pack de potencia ha demostrado sus cualidades en numerosos procesos de alta presión y en distintos sectores. Icono de petróleo y gas Icono de olor a gas gris Icono de refinería Icono de petroquímicos Icono de químicos Icono de plásticos icono gris Icono de limpieza Icono de cosméticos Icono de farmacéutico Icono de alimentos Icono de energía Otro icono

More DetailsDescargas

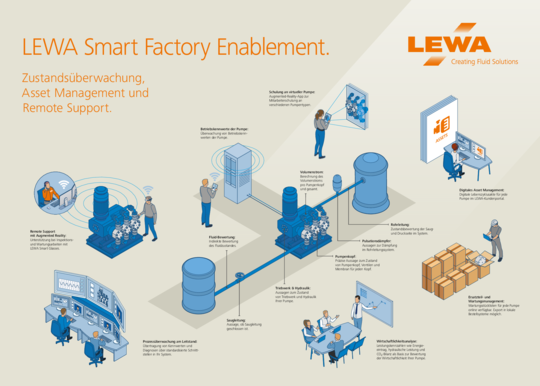

LEWA Digitale Services

Zustandsüberwachung, Asset Management und Remote Support.

5 MB

| pdf |

29.09.2022

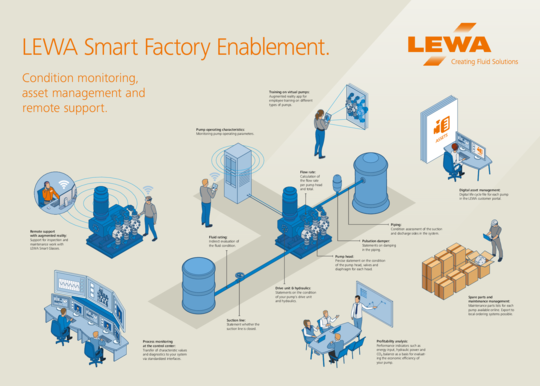

LEWA Digital Services

Condition monitoring, asset management and remote support.

5 MB

| pdf |

29.09.2022

LEWA Smart Factory Enablement

LEWA Smart Factory Enablement Poster 700x500 EN

1 MB

| pdf |

17.07.2022

LEWA Smart Factory Enablement

LEWA Smart Factory Enablement Poster 700x500 DE

1 MB

| pdf |

17.07.2022